Processing Your Payment

Please do not leave this page until complete. This can take a few moments.

Manufacturers are building for the new space industry

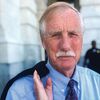

Photo / Tim Greenway

Patrick Sullivan, FMI’s technical project manager, says few materials can withstand the extreme conditions of the space environment.

Photo / Tim Greenway

Patrick Sullivan, FMI’s technical project manager, says few materials can withstand the extreme conditions of the space environment.

Temperatures reaching thousands of degrees. Brutal cosmic conditions. Novel exploratory missions traversing billions of miles for years at a time.

From satellites coursing through Earth’s atmosphere, to planets and moons within the unassisted human gaze, to extraterrestrial bodies that inspire wonder, products made by Maine companies are part of a new global space industry that is today exploring Mars, circling the moon and sampling interstellar dust in a quest to determine the origin of life and the universe.

A Lewiston company makes components for NASA’s moon and Titan programs. A Biddeford manufacturer develops thermal protection systems for Mars. Brunswick startups are building rockets and satellite ground support equipment.

The challenges of manufacturing for extreme conditions are technical and inventive. We checked in with some of these companies.

Brutal conditions

Biddeford composite manufacturer FMI, a subsidiary of Spirit AeroSystems (NYSE: SPR), produces reinforced thermal protection composites for products that must endure high temperatures.

FMI has worked with NASA for decades and has been involved with some of that agency’s most prominent projects. These include the heat shield used on the Stardust mission, in which a 390-kilogram robotic space probe launched in 1999 to travel three billion miles, collecting dust samples from the coma of comet Wild 2, as well as samples of cosmic dust, before returning to Earth in 2006. FMI’s heat shield, protecting Stardust’s reentry, had protective insulating panels made from a composite material that was developed by NASA. The heat shield had to live up to tough specifications, protecting the robotic capsule from temperatures that hit thousands of degrees Fahrenheit in brutal cosmic conditions.

FMI fabricated composite heat shield thermal protection systems for NASA’s Mars Science Lab, which landed the robotic rover Curiosity on Mars in 2012; and for NASA’s OSIRIS Rex mission, expected to return in 2023 with samples from a near-Earth asteroid called Bennu for analysis. The heatshield is critical for bringing the sample back to Earth, as it protects the craft and its contents from the 4000-degree F temperature resulting from the 27,000-mile-per-hour atmospheric entry.

FMI fabricated the thermal protection system for the transport and entry aeroshell that is part of NASA’s second Mars mission, which landed the Perseverance rover in 2021.

It manufactured a heatshield that will allow for the Dragonfly spacecraft to enter Titan’s atmosphere.

The company has been involved in the Artemis/Orion mission since 2007, providing critical propulsion components for the craft’s launch abort system that is designed to safely steer the Orion crew away from the space launch vehicle as needed during the flight to space at either the launch pad or during ascent.

Development of FMI’s heatshields starts with high-performance woven carbon fiber impregnated with resin to create a “ceramic matrix composite” that is particularly tough, withstanding erosion and other forces that might otherwise result in materials failure, says Patrick Sullivan, FMI’s technical project manager.

“Essentially, you want a material that’s going to erode as little as possible in an extremely high-temperature environment,” he says. “There are very few materials that can withstand these types of temperatures.”

Critical to the material’s development is its low thermal conductivity and its properties as it’s depleted during operation. For NASA, says Sullivan, ablation must occur in a way that’s easily modeled and predicted.

“No material will withstand this environment indefinitely,” he says. “We need to know how long they’ll ablate and how long they’ll last in the environment.”

Moon shots

Elmet Technologies, a Lewiston manufacturer of high-performance tungsten and molybdenum components for the aerospace market, recently supplied parts for the Orion space capsule, part of NASA’s Artemis mission that will bring astronauts to the moon for the first time in 50 years.

The first uncrewed mission to the moon and back launched in November. That will be followed by a crewed flight.

For Orion, Elmet manufactured aerospace-grade tungsten heavy alloy ballast weights, ranging from 7 to 33 pounds, for the heatshield. The job included pressing, sintering and machining, plus mechanical and ultrasonic testing.

Other space-related contracts have included machining molybdenum parts for space-based missile defense detection systems, space satellite surveillance imaging systems and space satellite GPS systems.

New this year is a contract with NASA’s Dragonfly Program, a small rotorcraft expected to launch in 2026 and in 2034 arrive on Titan, a moon of Saturn about 800 million miles from Earth, to collect soil samples. Elmet is supplying custom-machined thin molybdenum shells to use in a small furnace onboard Dragonfly.

Specifications for space applications, said Elmet’s director of quality and continuous improvement, Dan Drinan, include the ability for the components to operate and maintain strength at temperatures ranging just below negative-400 degrees Fahrenheit to over 350 degrees F.

Elmet has adapted with investments in tooling, technology and quality processes, and expanded to meet material specifications and demands.

“Cleanliness of parts used in spacecraft and satellites must be strictly controlled to prevent small particles or debris from floating around and possibly damaging sensitive electronic circuitry,” said Drinan.

To guarantee no debris in or on machined holes and surfaces of the parts, special hydrogen furnaces are used to clean tungsten and molybdenum products prior to final packaging.

Biofueled rocket

On Jan. 31, 2021, bluShift Aerospace Inc., headquartered at Brunswick Landing in Brunswick, made history at Loring Commerce Centre in Limestone when it launched Stardust, the world’s first commercial prototype rocket to be powered by near carbon-neutral, nontoxic fuel.

Founded in 2014, bluShift designed the bio-derived rocket fuel and a modular hybrid rocket engine, called the MAREVL or Modular Adaptable Rocket Engine for Vehicle Launch, and is working toward building a commercial rocket operation that can lift small payloads to low-Earth orbit.

This year, the company conducted a successful first burn of its full-scale MAREVL. It’s working on the fuselage design for its first suborbital rocket, Starless Rogue, designed to provide nanosatellite client payloads six to eight minutes in zero gravity.

BluShift is developing a telemetry system, conducting more engine testing and finalizing its Federal Aviation Administration licensing. The plan is to launch Starless Rogue from NASA’s launch facility at Wallops Island, Va. Founder and CEO Sascha Deri is pursuing launch opportunities in Maine, with plans to build a larger orbital rocket.

In Q1 2023, bluShift will begin a $10 million seed round to fund Starless Rogue’s full buildout, regulation compliance and launch.

“We’ve received $9.5 million in purchase orders and letters of intent from customers, ranging from commercial companies wanting to test out technology to be used in space and student experiments to professional academic research experiments and people and pets’ ashes being launched for memorial services,” says Deri.

Plating for a spaceplane

Silvex Inc., an aerospace-certified company in Westbrook, has been providing chemical processing services for components on Broomfield, Colo., Sierra Space Corp.’s Dream Chaser program.

Silvex serves industries including defense, firearms, aerospace, electronics, alternative energy and restaurant/hotel-ware.

Dream Chaser is a winged commercial spaceplane in development to fly resupply missions for the International Space Station.

When it comes to chemical processing, proper and consistent solution maintenance is essential, says George Johnson, Silvex’s director of operations.

A significant challenge includes fine-tuning the configuration of the tanks in which the components are plated, in a way that ensures a uniform coating around and within the parts.

“Making sure that the electrical distribution going into the tanks and the chemical solution itself are all in sync, with no hot spots or areas of weak circulation, is essential,” Johnson says. “This fine-tuning is where the experience of our employees really shines and comes into play.”

Another challenge, he says, is the transition to aerospace participation in general, involving a much higher degree of documentation and material traceability through new shop floor control and lab analysis software and upgrades of numerous information technology hardware and communications protocols.

Satellite support

Greisen Aerospace, at Brunswick Landing, designs and manufactures satellite ground support equipment, including specialized lifting hardware used by the aerospace and defense industries.

Daniel Greisen founded the company in 2014. In 2019, he delivered on a major contract with Boeing Satellite Development Center, a business unit of Boeing Defense, Space & Security, to build a ground-support fixture that can lift and manipulate the bus module, or bottom half, of a Boeing communication satellite called the 702MP.

“This is a pretty heavy piece of hardware,” says Greisen. “They have to move it around to access various parts of the propulsion system.”

The challenge was to design a fixture that would grab the top of the module, which is about 13 feet in diameter and weighs about 5,000 pounds, and lift it up and down and spin on a vertical axis without risk of failure. The fixtures are designed with strength and redundancy in mind.

“What makes them interesting to design is that, although they’re made of welded steel, for the most part — much like many pieces of machinery — they are designed to not have any place where, if one component were to fail, the whole thing would fail,” he says. “We made sure that, if any bolt or weld failed, the fixture would still work.”

For example, there’s a large screw that’s key to moving the satellite up and down. Rather than the screw having just one nut, it has two.

“The first nut normally does all the work,” he says. “But if that were to fail, there’s another underneath it to catch it. So there’s a lot of redundancy built in.”

The Boeing plant in question is in California, so Greisen also designs for the possibility of earthquakes.

“We have to make it stronger and make sure it takes a good sideways load,” he says.

0 Comments