State-of-the-art composites research lab moves into USM's Dubyak Center

Courtesy / USM Office of Public Affairs

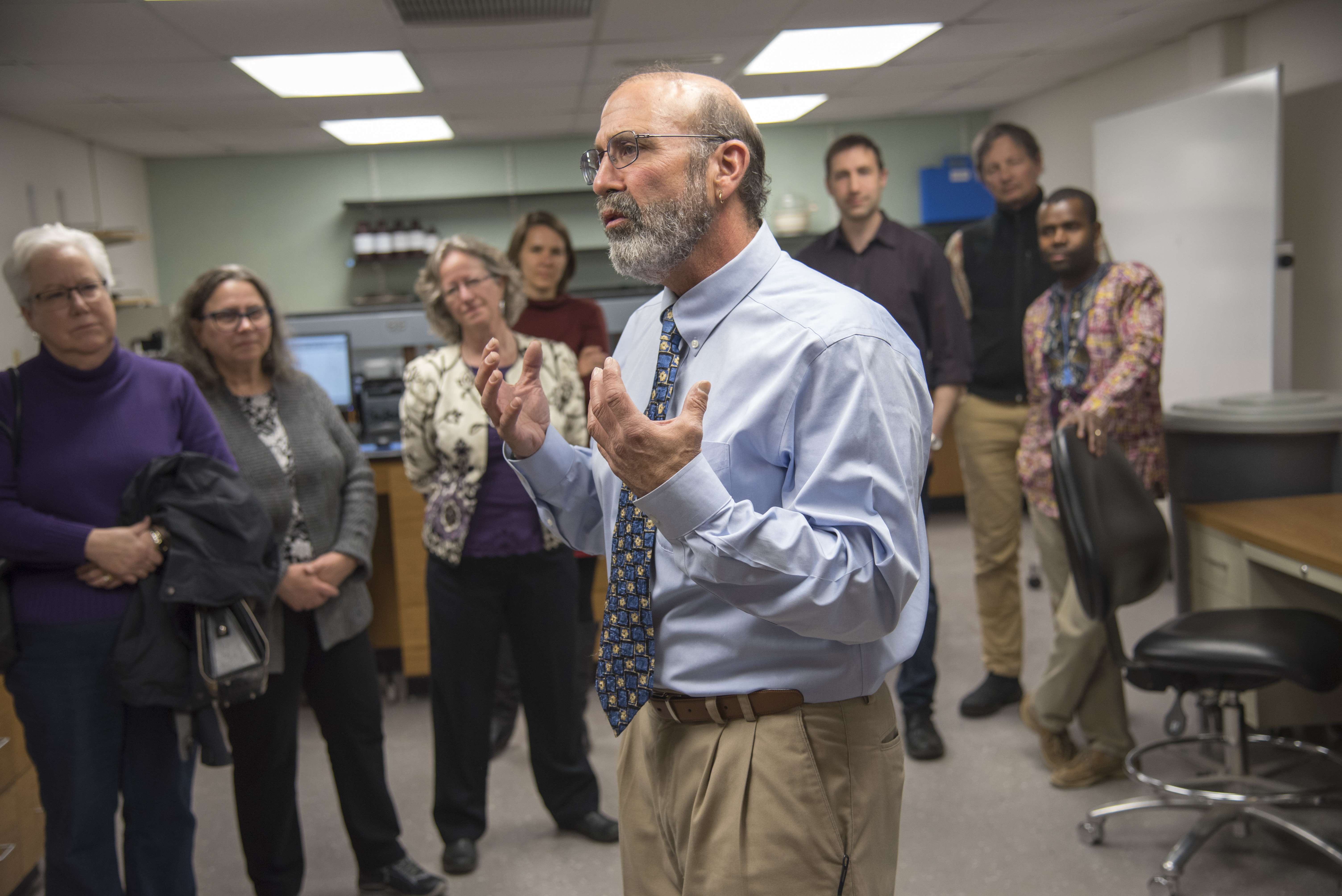

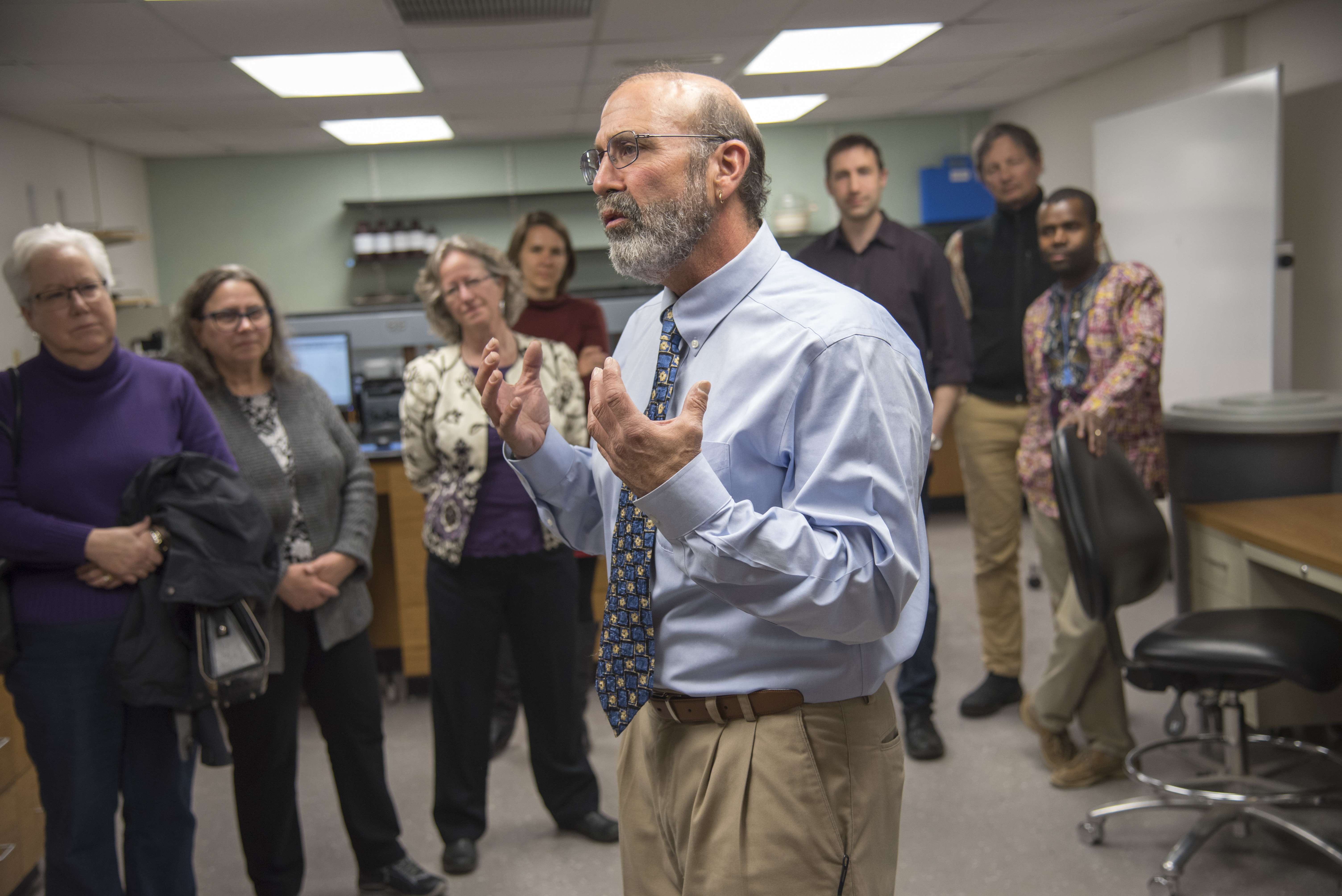

Stephen Von Vogt, left, managing director of the Maine Composites Alliance, and Glenn Cummings, president of the University of Southern Maine, sign the collaboration agreement that places MCA’s Composites Research Engineering Laboratory and its $1.5 million worth of equipment at USM’s Michael E. Dubyak Center for Digital Science & Innovation.

Courtesy / USM Office of Public Affairs

Stephen Von Vogt, left, managing director of the Maine Composites Alliance, and Glenn Cummings, president of the University of Southern Maine, sign the collaboration agreement that places MCA’s Composites Research Engineering Laboratory and its $1.5 million worth of equipment at USM’s Michael E. Dubyak Center for Digital Science & Innovation.

The Composites Research Engineering Laboratory that had been located at TechPlace, Brunswick Landing’s technology accelerator, has a new home at the University of Southern Maine in Portland.

For Stephen Von Vogt, CEO of Maine Marine Composites and managing director of the Maine Composites Alliance, USM is the ideal spot for CERL and its $1.5 million worth of equipment now set up at the Michael E. Dubyak Center for Digital Science & Innovation at USM.

“TechPlace was a good place for us,” Von Vogt told Mainebiz in a phone interview, “but we didn’t have access to the faculty and students that we’ll have being located on the USM campus. We see this as a great opportunity for the composites industry and for students in the applied science programs.”

Von Vogt said a good indicator of the composite industry’s interest is the estimated 25 companies that attended Friday’s announcement of the new collaboration bringing CERL and its state-of-the-art equipment to USM. The laboratory’s director is Andrew Schoenberg, a 40-year veteran of the semiconductor and plastic manufacturing industry who is considered to be one of the leading composite manufacturing experts in the Northeast.

Having a program with state-of-the-art equipment and opportunities for USM engineering and applied-science students to gain hands-on experience in the composites field is a win for companies with chronic needs for skilled workers ... as well as for students who’ll be looking for work once they graduate, Von Vogt said.

“Maine Composites Alliance and CERL sought this relationship with USM so that we could solve the problem of workforce development,” Von Vogt said. “Being at USM will allow us to teach students about material science, engage them in the technical problems that CERL is solving for industry, and then place them with the companies in Maine and New England that desperately need their assistance.”

“For us and the university it was a great opportunity to show off the lab,” he said, noting that Friday’s announcement and tour was attended by representatives from Kenway Corp., Ocean Renewable Power Co., STARC and TPI Composites, among other companies.

“Composites are used in every industry,” he added.

CERL’s clients range from companies that build surfboards to global manufacturers of composite wind blades for the wind energy market.

Workforce development

Among those attending Friday’s event was Stephen Nolet, principal engineer and senior director of innovation and technology at TPI Composites Inc. of Scottsdale, Ariz., the largest U.S.-based independent manufacturer of composite wind blades, which announced earlier this year a multi-year supply agreement with Vestas Wind Systems to provide blades for India and other export markets.

“The workforce development aspect of this mission — combined with the assets to serve the community — is a win-win for all of us,” said Nolet. “I personally look forward to driving the educational experience: internships, capstone projects and other real-life opportunities for students.”

For Schoenberg, locating CERL at USM fulfills the third leg of the lab’s threefold mission of providing analytical services, product development and education. While the largest segments in Maine’s composite industry are boat-building and marine infrastructure materials, aerospace, wind and ocean energy, construction and transportation are markets also driving its growth.

Capturing those markets, both Schoenberg and Von Vogt know, hinges on the availability of workers who not only know composite materials and their capabilities, but are also comfortable with the design-build-test approach used by successful entrepreneurial manufacturers.

“It’s about incorporating into an organization that will allow [CERL] to thrive and go forward and help both industry and academia,” Schoenberg said. “Now it’s going to embedded in a wonderful university that will allow it to continue grow. We want to help students get jobs and to raise the technology of Maine.”

USM President Glenn Cummings agreed, saying: “Students will benefit. Faculty will benefit. The composite industry will benefit Maine industry and future Maine employers will benefit. It will continue to put USM at the center of making our economy and our state asset-based, strong and adding deep value to the people who go out and lead the next generation of industry and business.”

Located within the Michael E. Dubyak Center for Digital Science & Innovation — which was established in October 2018 with a $1 million gift from the current chairman and former president and CEO of WEX — CERL becomes part of a center that will include digital classrooms and "ideation" space, a cybersecurity cyber-range and computer science research center, and a prototyping manufacturing space.

Jeremy Qualls, the dean of USM’s College of Science, Technology and Health, welcomed industry leaders to interact with the university and extended an open invitation to employers to partner with the new state-of-the-art center to work directly with the students who will be part of the emerging skilled workforce after they graduate.

“Let us know what you need,” he said. “What skills are you trying to develop? We’ll see what we can do to help. … We’re creating pipelines for the technical workforce,” Qualls said.

Steve Levesque, executive director of Midcoast Regional Redevelopment Authority, which oversees the redevelopment efforts at Brunswick Landing, said CERL’s vacated spot at TechPlace already is being filled.

“We have another tenant for the space,” he said. “Companies do come and go. Obviously, the whole concept of TechPlace is to help entities find their footing and then move out when they’re ready. The fact that they are able to move to USM is great; they’re still a partner of ours.”

0 Comments